The industrial history of Cedar Rapids, Iowa, is linked to the city’s close proximity to the river and railway, which made the transportation of goods and supplies more efficient. In November of 1871, Thomas McElderry (T.M.) Sinclair expanded a successful family meatpacking business by opening his own plant in Cedar Rapids, capitalizing on the city’s resources. Within a few years, T. M. Sinclair & Co. became the largest meatpacking plant in Iowa and the fourth largest in the world.

In 1832, T.M.’s father and uncle, John and Thomas Sinclair, organized a meat processing company in Belfast, Ireland. The J. & T. Sinclair Company processed pork for bacon and ham to be sent to England. The family opened a branch in Liverpool, England, where John’s son, T.M., learned the family trade.

In 1862, T.M. and his cousin, John, opened an American branch of the company in New York before looking to the west to establish production closer to the source of the product. David Blakely, an employee of Sinclair & Co. moved to Cedar Rapids and suggested the city as a location for their new plant.

Railroads, which connected Cedar Rapids to Chicago in 1859, helped secure the venture’s success. Trains shipped Sinclair & Co.’s products east and brought new residents to Cedar Rapids. By 1870, the population had more than tripled— from 1,830 to 5,940 people. In four years, approximately 400 people worked at Sinclair & Co., making it one of the largest employers in the region.

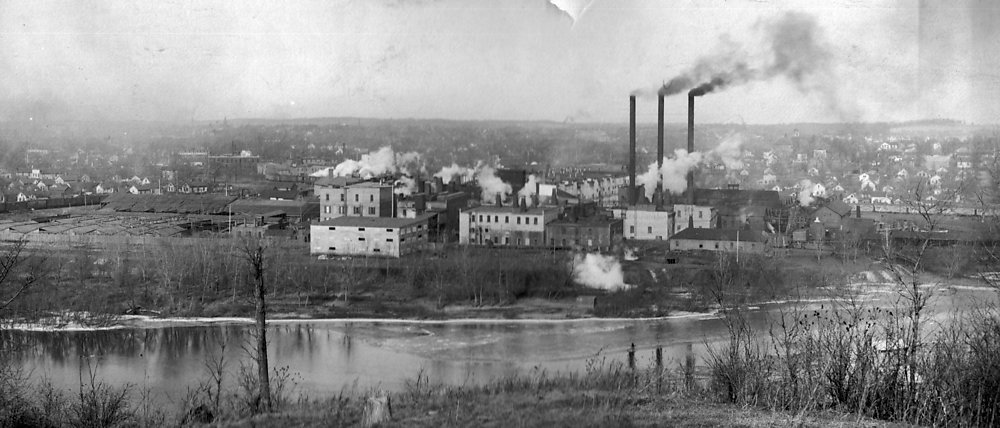

The first Sinclair & Co. plant in Cedar Rapids was in the heart of downtown on First Street Southeast in what had been the Higgins Icehouse. By 1872, the company purchased 16 acres of land along the Cedar River, just outside of the city limits. To maximize efficiency, the Northwestern Railroad agreed to lay tracks directly to the plant.

Sinclair & Co. became the second plant in the country to harvest river ice for ice refrigeration, which prevented meat from spoiling during warm temperatures. Meatpacking became a year-round business thanks in part to the plant’s proximity to the Cedar River.

Sinclair & Co. processed an average of 3,000 hogs per day during the winter and 1,000 per day during the summer. Despite the bad smell and waste created by the plant, many praised the benefits of this industry:

“We doubt if even our citizens really appreciate the extent of this mammoth institution which is silently but surely making Cedar Rapids the pork market of Central Iowa. […] The other day we took a look through the institution, witnessing the killing of hogs at the rate of one thousand a day […] Go through the cellars of this establishment and drive all thoughts of famine, for years to come, from your head. […] Do we all, and especially the farmers, appreciate the immense benefit of such an institution? We can scarcely estimate the amount to which this one institution contributes to our prosperity.”

The Times, December 4, 1873

On March 24, 1881, T.M. died after falling into an elevator shaft while he was inspecting the plant. His brother-in-law, Charles Soutter, having worked in the New York packing house, assumed control of the company until 1889. Charles expanded Sinclair & Co., increasing employment and hog slaughter.

By 1913, competition from Danish sources of bacon and ham in the British market weakened the Sinclair & Co. business and the Chicago firm Schwarzchild and Sulzberger purchased the company. In January of 1930, the Sinclair family withdrew from the business and total operations were assumed by Wilson & Co., the successor to Schwarzchild and Sulzberger.

The Midwest meat market came to be dominated by Wilson & Co., Hormel, and Oscar Meyer. Wilson & Co. operated the plant in Cedar Rapids until July 2, 1984 when it was purchased by Farmstead Foods and operated by Cedar Rapids Meats, Inc.

The Cedar Rapids plant closed March 8, 1990, and six days later, Farmstead Foods filed for bankruptcy. After severe flooding in 2008, the City of Cedar Rapids initiated demolition of the buildings on the site.

For more information about the Sinclair & Co. manufacturing history and site, see the Site Inventory Form.