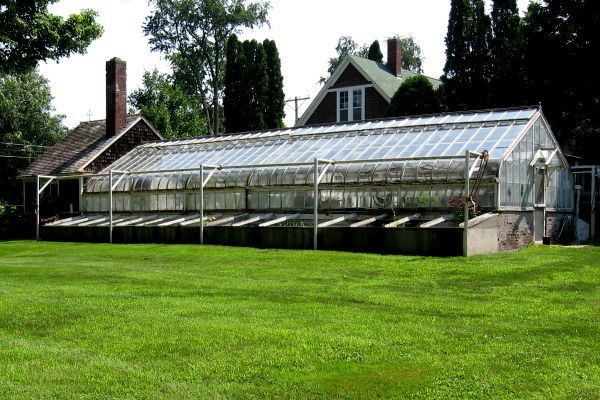

From 2011 to 2012, Brucemore rehabilitated the historic Lord & Burnham Greenhouse in the heart of the estate.

Around 1915, the Douglas family purchased the Lord & Burnham Greenhouse to provide gardeners with an enclosed space in which they could start plants for the gardens and provide a source of fresh flowers during the winter.

Originally, the structure consisted of a small head house, a glasshouse, and detached cold frames in the rear. The Halls doubled the size of the glasshouse to 900 square feet in 1940 and moved the cold frames to the sides. These modifications proved to be inappropriate for growing and interpretation purposes.

Consequently, the Brucemore Board of Trustees and the National Trust decided to restore the building to its original design — small head house, a 450 square-foot glasshouse, and several detached cold frames on the south lawn.

However, the modern, efficient furnace and mechanized vent and shade systems make this space a fully operational growing space.

The Douglas family head gardener, Archie White, utilized every inch of the Lord & Burnham Greenhouse during his tenure in the 1920s and 1930s, including the head house basement where pots and dirt were stored.

The Douglas family head gardener, Archie White, utilized every inch of the Lord & Burnham Greenhouse during his tenure during the 1920s and 1930s, including the head house basement where pots and dirt were stored.

Howard Hall frequently hired employees from his Iowa Manufacturing and Iowa Steel and Iron Works companies to work at Brucemore during slow production times. With their help, Howard doubled the size of the greenhouse and moved the cold frames to the east and west sides of the building.

The greenhouse structure slowly fell into disrepair, especially after the furnace was turned off in 2006. Brucemore gardeners used the larger, Ludy greenhouse located near the Cutting Gardens after it was built in 2000 for their growing needs. A 2010 conditions assessment listed the LAB structure’s survival a “miracle” considering the severe iron corrosion.

In 2011, contractors removed the addition and wood rafters to stabilize the steel structure. The Lord & Burnham Company only used high quality wood for their glasshouse construction. At Brucemore, the rafters were made of old growth cypress featuring 100 rings per inch. Since this material is no longer readily available and a lesser wood could not withstand the greenhouse climate, contractors replaced the wood rafters with extruded aluminum of the same delicate profile.

After contractors erected the new aluminum rafters and the original cypress side vents and end gable, they installed new safety glass throughout. The final result of the Lord & Burnham Greenhouse Rehabilitation project is a fully operational greenhouse filled with plants. Despite modern materials and mechanical systems, experts consider this building 98 percent original.

Brucemore features an early twentieth century Lord & Burnham Greenhouse once again. Although a typical kitchen greenhouse of that era, the classic curved-glass eave and small scale has put others of its kind at risk throughout the country. This building offers both a window into the past as well an opportunity to learn about modern ecology.

Staff now use this space for its historic purpose of cultivating plants.